Understanding the Value of Welding Inspection Madison in Building

Understanding the Value of Welding Inspection Madison in Building

Blog Article

Just How Effective Welding Evaluation Boosts Structural Honesty and Longevity

In the world of construction and design, the relevance of welding inspection can not be overemphasized, as it plays a crucial function in ensuring structural stability and expanding the lifespan of jobs. Sign up with the expedition of exactly how effective welding assessments can change prospective vulnerabilities into staminas, adding to the enduring success of building and constructions.

Value of Welding Evaluation

Guaranteeing the architectural integrity and safety and security of welded constructions mandates extensive welding examination processes. Welding evaluation works as an essential protect in the building and construction and production sectors, where the stamina and durability of joints substantially affect the general performance of frameworks. This assessment makes sure that welds satisfy certain standards and specs, decreasing the risks related to structural failures. The consequences of insufficient welds can be disastrous, bring about expensive repairs, functional downtimes, or also disastrous failures, every one of which highlight the extremely important importance of comprehensive examination.

In enhancement to security, welding inspection plays a crucial duty in high quality assurance. By sticking to predetermined requirements, assessments identify the uniformity of welds, making sure that each fulfills the wanted stamina and visual demands. This uniformity is necessary not just for safety but additionally for keeping the reputation and integrity of manufacturers and makers. Governing compliance is a significant vehicle driver of welding inspection techniques. Sector standards and codes, such as those from the American Welding Society (AWS) or the International Company for Standardization (ISO), necessitate adherence to strict guidelines, emphasizing the significance of examinations in meeting these professional and lawful obligations.

Trick Assessment Techniques

Ultrasonic Checking (UT) makes use of high-frequency acoustic waves to discover subsurface problems, supplying precise information regarding weld stability without creating any kind of damages. Radiographic Testing (RT), involving X-rays or gamma rays, offers an in-depth picture of the weld's inner framework, disclosing surprise blemishes. Magnetic Particle Testing (MPT) is another non-destructive method, particularly effective for discovering surface and near-surface stoppages in ferromagnetic materials.

Penetrant Screening (PT) entails the application of a fluid color to disclose surface-breaking flaws, using a simple and economical option for non-porous materials. Each technique has its specific applications, toughness, and constraints, and commonly a mix of techniques is employed to attain detailed inspection outcomes. Mastery of these techniques boosts the reliability and longevity of welded structures, straightening with safety and security and performance expectations.

Identifying Common Issues

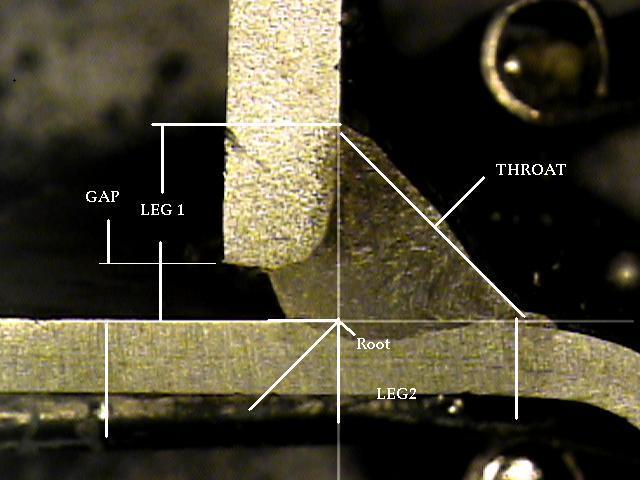

Porosity, identified by gas pockets within the weld, decreases the weld's stamina and durability. It typically arises from contaminants or incorrect protecting gas. Splits, which can occur during or after click here now welding, present substantial risks due to their prospective to circulate under stress and anxiety. They frequently develop from too much stress, fast air conditioning, or inappropriate weld design.

Insufficient combination, where the weld metal fails to bond entirely with the base product, weakens the structural integrity, leading to weak joints. Slag incorporations happen when non-metallic materials are trapped in the weld, endangering its stamina and quality.

Identifying these issues with precise inspection approaches, such as visual evaluation, ultrasonic testing, or radiography, is critical. Resolving these worries guarantees weld quality, eventually supporting the architectural stability and safety of the constructed setting.

Enhancing Architectural Performance

Recognizing the importance of determining common weld problems normally leads to checking out approaches for enhancing structural efficiency. The fundamental approach for enhancing efficiency entails employing sophisticated welding strategies and materials that reduce flaw event. Utilizing high-quality filler products and making certain proper heat control can considerably reduce problems such as porosity and fracturing, thereby enhancing the weld's integrity.

Incorporating state-of-the-art welding innovations, such as laser welding and rubbing mix welding, more amplifies architectural resilience. These methods supply remarkable precision and reduced thermal distortion, directly affecting the resilience and strength of the welded structures. Moreover, taking on automated welding systems can ensure repeatable and constant weld high quality, lessening human mistake.

Additionally, executing rigorous pre-weld and post-weld procedures is essential. Correct joint style, surface area prep work, and look at more info stress-relieving procedures add to ideal weld performance. Conducting detailed pre-weld assessments allows for very early discovery of possible issues, promoting timely improvements prior to they jeopardize the structure.

Long-lasting Advantages of Evaluation

With vigilant evaluation methods, the long-term benefits to architectural stability become increasingly apparent. Comprehensive and consistent welding inspections play a vital role in avoiding structural failures by identifying flaws and inconsistencies early in the building and construction process. This positive technique makes certain that potential issues are attended to before they can jeopardize the safety and security and longevity of structures. By capturing issues early, pricey fixings and downtime are decreased, inevitably prolonging the lifespan of the facilities.

Moreover, routine examinations add to preserving conformity with sector standards and guidelines, thus avoiding legal and monetary effects. This adherence to quality control not just enhances the integrity of the framework however also fosters count on amongst stakeholders, consisting of clients, engineers, and regulative bodies. The thorough documentation of assessment end results acts as a beneficial resource for future upkeep and repair service initiatives, facilitating notified decision-making.

Additionally, efficient evaluation techniques sustain advancement by incorporating advanced modern technologies such as non-destructive screening and electronic imaging, which can boost precision and performance. This technological combination additionally underscores the commitment to quality in architectural honesty. Ultimately, buying careful welding inspections is a sensible approach that generates significant company website lasting advantages, protecting both the monetary and physical financial investment in framework projects.

Verdict

Reliable welding examination plays a crucial role in improving architectural honesty and durability by determining issues early in the building and construction process. Using techniques such as visual examination, ultrasonic screening, and radiographic screening makes certain the discovery of issues like cracks and porosity that endanger weld strength. Extensive assessments ensure conformity with industry criteria, therefore extending the life-span of frameworks, minimizing pricey repair work, and fostering stakeholder depend on in the dependability and safety of bonded building and constructions.

In the realm of construction and design, the relevance of welding assessment can not be overemphasized, as it plays a critical duty in ensuring architectural honesty and prolonging the life expectancy of jobs.Making sure the structural stability and safety of bonded constructions mandates rigorous welding inspection processes.Building upon the significance of welding inspection in securing structural integrity, comprehending the vital examination methods becomes critical for reliable implementation. Effective welding assessment incorporates a variety of techniques created to review weld top quality, guaranteeing compliance with strict engineering criteria - Welding Inspection Madison.Reliable welding evaluation plays a critical duty in improving architectural integrity and durability by recognizing problems early in the construction procedure

Report this page